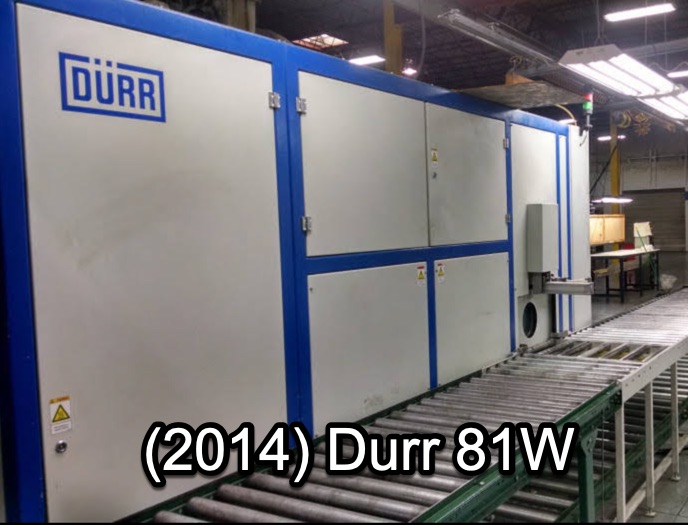

Specifications

Cleaning and drying process in a vacuum-proof work chamberWork chamber is fed from the front, manually or automatically

Automatic work chamber door locking

Rotation and oscillation movements to support the cleaning and drying effect

Integrated full-flow filtration

Integrated oil separator

Siemens S7 PLC control system for custom programming of process sequences

Error diagnosis via plain text display on operator control panel

Closed system housing with maintenance doors for optimum access

Optional extras

Third flood tank for additional rinsing or preservation

Waste water-free operation due to integrated Aquaclean treatment unit

High-power injection flood washing

Ultrasonic unit

Vacuum drying

Cartridge filter for fine cleaning

Automatic conveyor

Automatic basket lid placement

Ion exchanger for demineralisation

Advantages

Compact design, ready to connect up

Multi-step washing/rinsing process with hot-air and vacuum drying

Waste water-free operation possible

All parts coming into contact with media are made of stainless steel

Plenty of scope for expansion due to modular design

Notes

2 tanks with full stream filtration Oil separator

Hot air drying

Weekday timer

Eight cleaning programs Status lamp

Options included:

Sight glass

3rd tank for conservation

Cartridge filter per tank

Cross contamination reduction

Aquaclean system for waste water free operation

Additional rinse water preparation via Aquaclean

Vacuum drying 100 m3/h

Ultrasonic device 3 kW

High power injection flood wash

Manual loading, 3 positions

Dosing unit for FT1+FT2 and FT3

Automatic basket closure

Leakage warning sensor

Machine roof

Installation supervision and training (5 days – 8 hours per day) Packing, freight and duties (DDP Chesterfield, MI)